Humans have an innate thirst for adventure and an instinctive desire

to expand their knowledge through firsthand experience. By testing

the limits of personal strength and endurance, we obtain a better

understanding of ourselves. One aspect of adventure is the art of

competition. Team AeroVelo, comprised of professionals and

engineering students from the University of Toronto, pursue this

quest for adventure by joining others in an attempt to set the world

human-powered speed record.

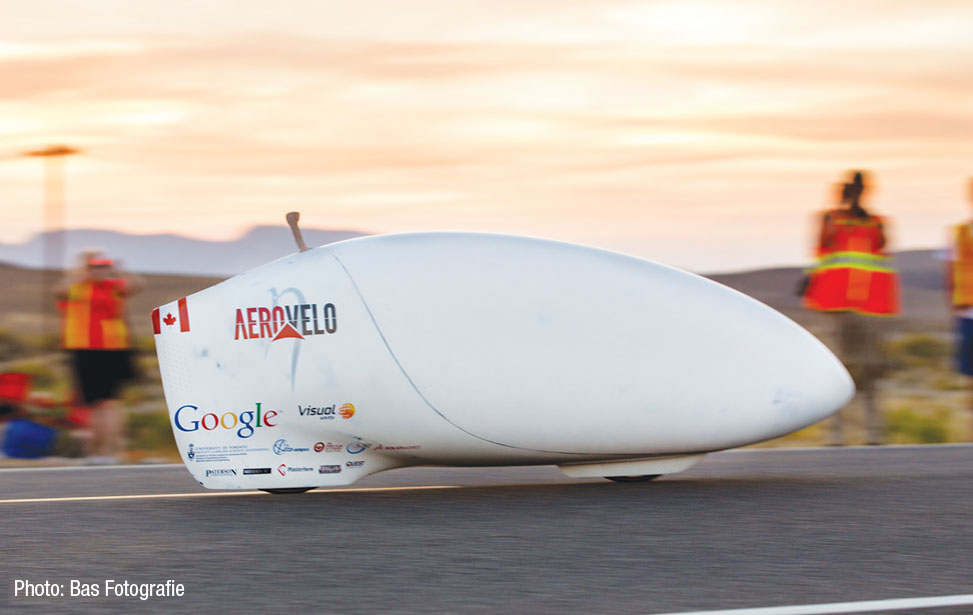

Every year, teams gather from around the world to compete at the

World Human-Powered Speed Challenge (WHPSC) in Battle Mountain,

Nevada. Team AeroVelo brought their newly designed “Eta” speed bike

to the 2014 competition. AeroVelo, an elite design and innovation lab,

pursues engineering projects that foster a sense of adventure and passion

in scientific development, challenge the norms of conventional design,

and focus on a healthy, sustainable future.

“We’re very small and right now our main activities are the student

summer projects, public speaking & outreach and limited consulting

on wild engineering projects,” states Cameron Roberston, co-founder

of AeroVelo, Inc. "AeroVelo partners with the University of Toronto’s

Human-Powered Vehicle Design Team (HPVDT) and shares the team

workspace full-time during the summer," according to Robertson.

HPVDT, comprised of top-notch U of T undergraduate students

in aerospace, materials, and mechanical engineering, focuses on the

design and construction of innovative, high-performance human-powered

vehicles. The goal of the AeroVelo/U of T partnership is to provide

students with hands-on, practical engineering design experience that

promotes efficiency and sustainability while encouraging the reduction

of society's impact on the environment. Each year the student team has 4

months to engineer and build a human-powered vehicle.

Internal bike render.

The students do not receive college credit for participating in the

summer program. However, "The students' time at AeroVelo counts

toward a 600-hour engineering experience required of all graduates,"

Robertson said. “For students, it’s similar to a research internship in a

lab, but the design freedom, creative opportunities and time spent in

hands-on fabrication are above and beyond what is available elsewhere.”

Robertson has also indicated that, “This summer, all of the students have

been extremely motivated and have very quickly picked up on many of

the design concerns and tradeoffs in developing this year’s high-powered

speed bike. Students with no specialization in bicycles or aerospace have

quickly become familiar with both.”

“Eta,” the name of AeroVelo’s 2014 speed bike, is the Greek letter

used in engineering as the symbol for efficiency, and represents the team’s

goal of building the world’s fastest human-powered vehicle, capable of

breaking the current ground level speed record of 133.8 km/h (83.1mph).

The speed bike’s internal components are as equally fundamental

to the successful performance of the bike as the aerodynamic design. A

portion of Eta’s transmission is designed to use a more efficient chain

than what is typically used in bicycles. According to Alex Selwa, a

member of the U of T student engineering team, “Most bicycles have a

free-wheel which allows the wheel to rotate even when the pedals and

chain are stationary. In our front-wheel drive design we are not using a

standard bike chain and cannot use an off-the-shelf bicycle free-wheel.”

Instead, an overrunning clutch solution was required.

The Stieber CSK clutch was press fit onto the front wheel hub body, and pressed inside of the sprocket. It is responsible for driving the wheels up to 145 km/h (90 mph).

After careful research, the team contacted Formsprag Clutch in

Warren, Michigan to request an overrunning clutch solution. Formsprag,

an Altra Industrial Motion Company, donated a Stieber CSK25 PP

overrunning clutch to the AeroVelo team as part of Formsprag’s Student

Support Program. The CSK clutch was a clear choice to accommodate

the size and load requirements of the unique hub. “The front hub design

involved fitting many different components into a small and efficient

package. The clutch needed to be as small as possible in order to fit inside

the sprocket and stay within the width requirements of the hub,” explained

Selwa. “The clutch is press-fit onto the hub body and then pressed inside

of the sprocket. It is responsible for driving the wheels at speeds up to

145km/h or 90 mph.”

The Stieber Model CSK25 PP overrunning

clutch features ultra-hard Formchrome® sprags which provide extra-long life, maximum wear resistance and lower maintenance costs. Formchrome sprags – exclusive to Stieber/

Formsprag – are made by diffusing chromium into the surface of hardened high carbon alloy steel to form a chromium-carbide alloy.

Stieber’s model CSK25 PP is a bearing-supported sprag-type clutch,

delivered grease-lubricated and protected against dust particles as small

as 0.3 mm. It provides instant locking/engagement when the clutch shifts

from overrunning to engagement, with a maximum overrunning speed of

5,000 RPM and a 77.5 lb. ft (105 Nm) torque capacity. The sprag-type

backstop keeps the shaft from turning backwards with keyways on both

the inner and outer races that prevent the bearing from rotating on the

shaft. All CSK clutches feature Formchrome® sprags with chromiuminfused

steel that produces an ultra-hard surface to maximize wear

resistance, which results in extra long clutch life.

With the help of Stieber Clutch, Team AeroVelo’s Eta speed bike

reached a top speed of 126 km/h (78 mph) at the 2014 World Human-

Powered Speed Challenge. Although this time did not break the record,

many lessons were learned and more refinements are yet to come for next

year’s race. “Our goal with Eta is not simply to break a speed record. Our

goal is to reach such unbelievable speeds that it gets people to think twice

about preconceived limits of what is possible,” stated Todd Reichert, cofounder

of AeroVelo, Inc.

Stieber founded in 1937, Formsprag founded in 1947 and Marland

founded in 1932 make up the Altra Industrial Motion Overrunning Clutch

Group and are the world’s market leaders in the research, development

and production of overrunning clutches and backstops. Altra overrunning

clutch solutions are utilized in a variety of key industrial markets

including Packaging Machinery, Material Handling, Mining Aggregate,

Aerospace & Defense, Food & Beverage and Power Generation.

Innovative engineering and continuous product improvement, combined

with advanced technologies and responsive customer service has enabled

Altra Industrial Motion to provide solutions that consistently exceed

customer expectations.